Revolutionizing Road Maintenance: Sibom's Versatile Cold Planer for Urban Repairs

When people hear about Sibom Attachments, many immediately think of agricultural equipment, as Sibom has long been synonymous with farm machinery attachments. However, the product ecosystem of Sibom Attachments is quite extensive. This article will introduce another popular product from Sibom Attachments—the cold planer.

Typically, in road maintenance and repair operations, mechanical hammer and milling machines are commonly used for mending and excavating damaged road surfaces. However, hydraulic hammers have low construction efficiency, and the shape and depth of the excavation are difficult to control.

Milling machine are well-suited for large-scale construction operations but come with high operating costs. For small-scale repairs on urban roads, both tools have their limitations.

Therefore, researchers have opted for a compromise solution—the cold planer. Due to the skid-steer loader's ability to pivot in place and operate flexibly in confined spaces, cold planers are typically mounted on skid-steer loaders. This setup allows for precise, depth-limited milling of asphalt and concrete surfaces within small areas.

In most countries, cold planers are extensively used as the main construction equipment for the maintenance and renovation of urban roads. However, the high cost of most cold planers makes them unaffordable for many customers.

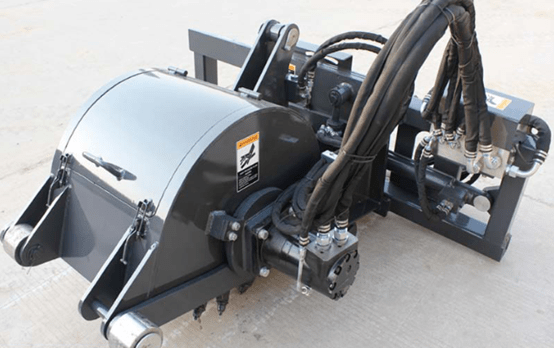

In response to market demands, Sibom has developed and designed a cold planer that matches the performance of its competitors but at a more reasonable price. Its efficiency and high-quality operation have won favor with an increasing number of users, and it continues to prove its worth in the demanding field of highway maintenance.

The Sibom cold planer belongs to the category of cold milling equipment. It can directly mill asphalt and concrete surfaces at ambient temperatures and offers a variety of drum sizes to choose from. The Sibom cold planer is cost-effective, features a wide range of milling depths that are adjustable, produces small particles (which can be used as backfill material), and ensures safety (its milling drum throws milled debris backward to prevent scattering). These advantages make it widely used in rental and public utility services.

Specifically, the application areas of the cold planer include:

- It is used for milling, crushing, and excavating worn asphalt and concrete surfaces on highways, urban roads, sidewalks, airports, and freight yards, in preparation for resurfacing and repairs, allowing for the laying of new material to refurbish the pavement.

- It is used for milling specific areas that require repairs, excavating pavement pits and trenches to create regular square trenches, which facilitate neat and visually appealing seams after repairs.

- It is employed to level common pavement deformations such as bulges, ripples, and ruts, enhancing the smoothness and drivability of the road surface.

- It performs texturing operations on surfaces with low friction coefficients to achieve a certain level of roughness, enhancing the skid resistance of the pavement.

- It is used for removing road markings, including traffic stripes, road signs, and zebra crossings.

- It can also be used in emergency rescue operations during icy, snowy weather, such as removing road ice. Additionally, the Sibom cold planer features a side-shift capability, allowing it to operate without needing to straddle curbs and ditches。

The functions of the Sibom cold planer, along with its versatility, high-quality work output, efficiency, recyclability of materials, and low construction costs, make it an essential piece of equipment for the mechanized maintenance of highways and urban roads. It is also a crucial tool for the recycling and reuse of old road surfaces.

The image described captures a scene where a skid-steer loader equipped with a Sibom cold planer is engaged in maintenance work on a highway.

The Sibom cold planer can quickly complete specified small-scale road milling and crushing tasks in a relatively short time, laying the groundwork for subsequent road resurfacing operations.

Despite its compact size, the Sibom cold planer is remarkably powerful. The host machine drives the cold planer's hydraulic motor through hydraulic oil output, providing strong and dependable power. This allows for immediate excavation and construction on small, damaged road sections, enhancing the efficiency of road resurfacing and the speed of pothole repairs, ultimately improving the quality of travel for residents.

The Sibom cold planer is a new "weapon" for enhancing highway maintenance efficiency, advancing the mechanization of maintenance, and reducing the physical strain on maintenance workers. Compared to traditional manual labor, it increases work efficiency by more than tenfold.

Leave a comment